FUCO® advantages over steel:

Lower machining time when compared with steels

10% lower density when compared with steels

Better thermal conductivity

Greater damping of vibrations

FAQ

Where to use FUCO®?

Versa Bar® can be used in the replacement of elements made of carbon steel, aluminum, bronze, brass and cast iron.

What are FUCO® advantages over steel?

The most significant advantages, among others, include machinability, lower density, better thermal conductivity and greater damping of vibrations.

What types of cast irons does FUCO® provide?

FUCO® is divided into two cast iron classes: gray and ductile.

How to know what type of cast iron is to be used?

Gray cast irons are recommended for applications that require moderate mechanical properties and good thermal conductivity. By their turn, ductile cast irons are recommended for applications that require high mechanical properties, resistance to wear and tightness.

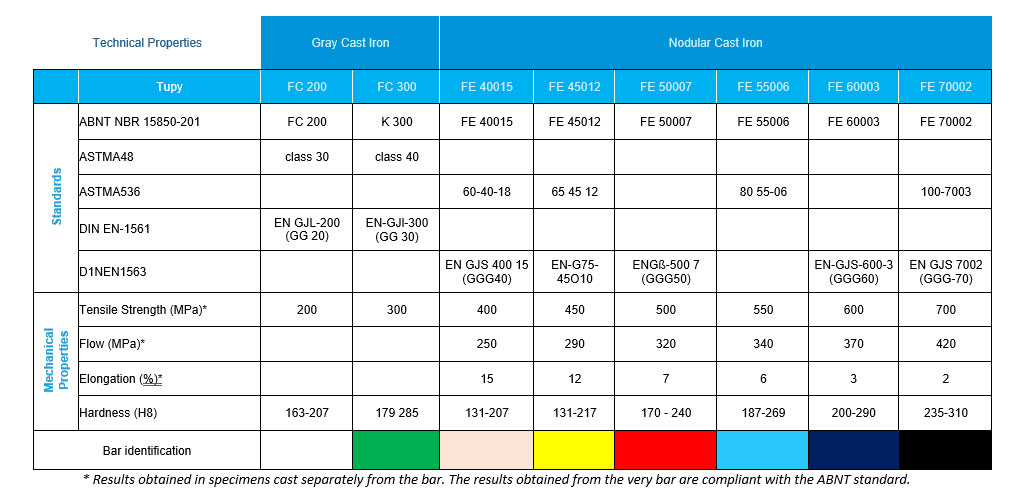

What are the classes and properties of cast irons?

May I carry out heat and surface protection treatments in FUCO®?

FUCO® may receive heat treatment with oil quench, which increases the hardness of the material, and consequently increases the resistance to wear. Among the surface treatments permitted, this includes galvanization, chrome plating, etc.

What are the financial benefits when FUCO® replaces steel?

The key economic advantages of using FUCO® in relation to steel are in the costs of the machining process and the lower density provided (10% less than steel), as graphite is present in its structure, and it makes easier breaking the chip and acts as lubricant for the cutting tool. Thus, we may reach a greater number of parts per hour with lower tool consumption.

What are the typical applications to use FUCO®?

| Classes | Applications |

|---|---|

| FC200 | Bushings, pulleys, rings, flanges, couplings, sheaves, spindles and counterweights, etc. |

| FC300 | Plungers, hydraulic valves, toothed racks, piston rings, guide rulers, molds, etc. |

| FE 40015/ FE 45012 | Hydraulic valves, manifolds, gears, nuts, shafts, glasswork molds, etc. |

| FE 55006/ FE 70002 | Components that require resistance to wear and surface heat treatments, shafts, gears, grinder bodies, valve seats, etc. |

Can FUCO® be welded?

Yes, but this requires special cautions; we recommend the use of nickel-based electrodes. Otherwise, HAZ (Heat Affected Zone) will become hard and brittle due to formation of carbides.

What type of tip is proper to machine FUCO®?

| ISO | MATERIAL | RECOMMENDED APPLICATION |

|---|---|---|

| K10-K15 | Gray and ductile cast iron | Drafting and semi-drafting Medium cut speed High feed Interrupted cut. |

| K05-K20 | Gray and ductile cast iron | Finish. High speed to wear. High speed. Medium feed. |

| K50-K20 | Gray and ductile cast iron | Medium semi-drafting machining. Low and medium cut speed Medium feed. Interrupted cut. |

Example: Class ISO K10 (ISCAR IC 418, GC3015 SANDVIK).

Comparative study of costs of parts manufactured with different materials by SOLID ROCK TECNOLOGIE (US), specialized in machining.

| MATERIAL | COST / PART |

|---|---|

| Steel 1020 | Raw material = 9.20 kg x R$ 4.55/kg =41.86 Machining = 9 min x R$70/h =10.50 R$ 52.36 |

| Steel 12L14 | Raw material = 10,1 kg x R$ 4,80/kg =48.48 Machining = 5.4 min x R$70/h =6.30 R$ 54.78 |

| Aluminium 6061 T6 | Raw material = 3.50 kg x R$ 18.0/kg =63.00 Machining = 2.4 min x R$70/h =2.80 R$ 65.80 |

| Versa Bar® FE 45012 | Raw material = 8.4 kg x R$ 5.50/kg =46.20 Machining = 3.2 min x R$70/h =3.73 R$ 49.93 |

The study demonstrates that FUCO® provides 25% cost reduction when compared with aluminum. In relation to steel 1020, FUCO® presents difference of 5.8 minutes in the machining time (65% reduction).

TupyCAD

Get to know the complete Tupy portfolio in the Pipe Fittings and Continuous Bars segment for use in AutoCAD™ and integrated quotation. Greater speed and perfection for your projects. Make free download.

link to collabo

Electronic Catalog

Access our electronic catalog to check, in greater details, the complete portfolio of products developed by Tupy.

link to collabo